WeylChem International GmbH

Allessa GmbH

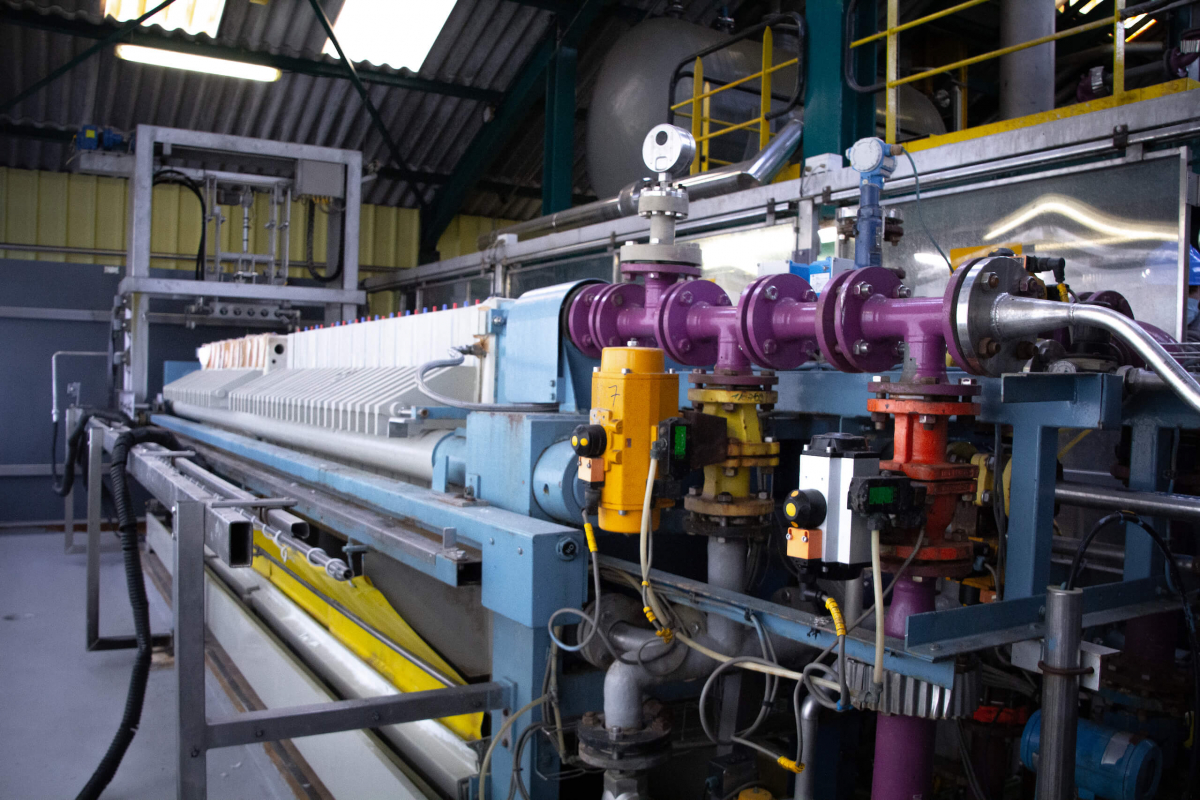

Capabilities

1 multi-purpose pilot plant for smaller scale (50 kg to 1 ton per year), reactors up to 1 m³ volume.

4 large-scale multipurpose plants for commercial volumes from 10 to 10.000 tons per year and product; reactor sizes up to 30 m³ volume

More than 200 batch reactors from 0,5 to 30 m3 volume summing up to over 2.000 m³ total reactor volume in a large variety of available materials as glass lined, ceramics, carbon steel, stainless steel of different grades, alloys, etc.

Expertise

Services

Technologies

Custom Manufacturing

Certificates

Location

Allessa GmbH